Waterproofing for Buildings – The Methods and Types of Waterproofing

Choosing the right waterproofing technique

according to the needs and requirements of the situation is one of the most

common construction woes. At the very least this waterproofing method should be

able to deliver for a long period of time.

The most common areas that require

waterproofing include:

- Wall-floor crevices

- Water featured in landscaping

- Foundations of basements

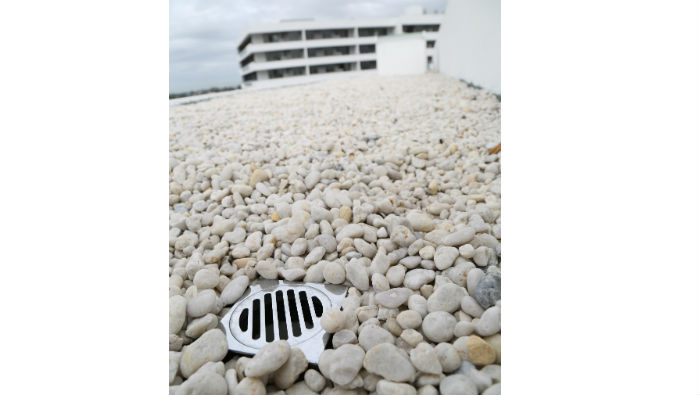

Waterproofing for buildings involves the creation

of impervious barriers over the surface of foundation, walls, roofs, and any

other areas of the structure of your building. This is done to prevent water

from penetrating through these surfaces and causing damages. With the help of

waterproofing, building surfaces are either made water resistant or even

completely waterproof.

|

| A roof appearing over a house after rain and after treatment by waterproofing membrane products. |

The most commonly used materials for

waterproofing constructions is polyurethane liquid membrane, liquid waterproofing membrane,

bituminous material, and cementitious material. Waterproofing structures and

buildings is typically required for swimming pools, water tanks, green roofs,

roofs or terraces, decks, balconies, kitchens, bathrooms, walls, and, of course,

basements of structures.

What Are the Different Types of Waterproofing Methods for

Buildings?

The most common types of waterproofing

methods used in construction include:

1. Polyurethane Liquid Membrane

2. Bituminous Coating

3. Bituminous Membrane

4. Liquid Waterproofing membrane

5. Cementitious Waterproofing

What is the Cementitious Waterproofing Method?

Cementitious waterproofing is among the

easiest methods of waterproofing for construction. You’ll find that the

materials used for cementitious waterproofing are quite easily available if you

know a few masonry product suppliers. Once you have gotten your hands on these

products, they will be ready to simply mix and apply on to the intended area.

Cementitious waterproofing is generally

used in areas that are internally wet like toilets. The type of waterproofing

used in this method can be described as semi-flexible or rigid and the

materials won’t be exposed to weathering or sunlight. Cementitious

waterproofing, therefore, does not work with expansion or contract processes.

The Applications of Cementitious Waterproofing

- Tunnels

- Parking lots and structures

- River channels/locks and concrete dikes

- Marine cargo docks and ports

- Subway and railway systems

- Dams

- Bridges

- Sewage treatment plants

Water treatment plants

What is the Liquid Waterproofing Membrane Method

Liquid membranes are thin coatings that

typically consist of primer coats and 2 coats of top coatings. These are

applied with the help of either trowels, rollers, or even sprays. The liquid waterproofing membrane

method is known to provide a little more flexibility as opposed to cementitious

types of waterproofing.

In this method, the liquid would cure into

what would seem like rubbery coatings on the wall. These rubbery coatings can

even reach as high as about 280% their original size. The durability of these waterproofing membrane

coatings will, however, depend on the types of polymers being used by the

manufacturers in the value chain of their products.

Liquid water proofing membranes are usually

found as spray-applied products and are mostly composed of asphalt that has

been polymer-modified. Polyurethane liquid membranes, on the other hand, can be

purchased in separate forms other than sprays such as for rollers or even

trowels.

What is the Bituminous Coating Waterproofing Method

Bituminous coating refers to types of

coating that are used for flexible protective coats and in accordance to the

polymerization grader or formulation. Its protection and flexibility against

water is highly influenced by its grade of polymer used alongside the

reinforcements of the fiber.

Bituminous coating is also known as asphalt

coating. These products work as excellent protective coatings and waterproofing

agents – especially in the case of foundations made of concrete.

This type of waterproofing coating is made

from materials that are bitumen-based and aren’t quite suitable for areas that

will be exposed to sunlight. This is so because the substance becomes quite

fragile and brittle after it has been exposed to sunlight. This won’t be the

case, however, if the product has been modified to work more flexibly such as

acrylic or polyurethane based polymers.

The flexibility of the finished products of

bituminous coating waterproofing will always depend on the bitumen and the

amount of solid contents of polymer that were added by the manufacturer.

What is the Bituminous Waterproofing Membrane Method?

The bituminous waterproofing membrane method is quite a

popular method that is used mostly for roofs that are low-sloped. This method

has been proven to be effective for such roofs for quite some time now and this

waterproofing membrane

method works either like a self-adhesive membrane or a torch-on membrane.

The self-adhesive compounds typically

consist of fillers, polymers, and asphalt. Other than this, they consist of

some oils and resins that are added to improve the product’s adhesive characteristics.

Those types of products that work like self-adhesives have low-shelf lives as

their bonding properties will begin deteriorating after some time.

Torch-on membranes, on the other hand, have

covered or exposed types. Exposed membranes often use mineral granular

aggregates in order to withstand the wear and tear they experience due to

weather. Covered types of waterproofing

membranes, will work if the contractor applies a protective screen onto

the surface in order to prevent the membrane from getting punctured.

What is the Polyurethane Liquid Membrane Waterproofing

Method?

Polyurethane liquid membranes are used for

waterproofing flat roof areas which may be exposed to harsh weather conditions.

This particular method of waterproofing is found to be quite expensive but also

offers its users with higher levels of flexibility.

Polyurethane has been found to be quite

sensitive to the moisture content present over its surface. This is exactly why

contractors need to be careful in evaluating the moisture contents in the

concrete slabs before application. If contractors aren’t careful, then the

de-bonding of these membranes will begin shortly after the application.

Are You Looking for Waterproofing Products?

Visit our website to browse waterproofing and tiling products along with the right tools and accessories for the job. You may also contact us by calling (02) 8119 6410 or visit our main website to check our portfolio at http://www.mrwt.com.au

No comments:

Post a Comment